Lag ledninger som forbinder verden.

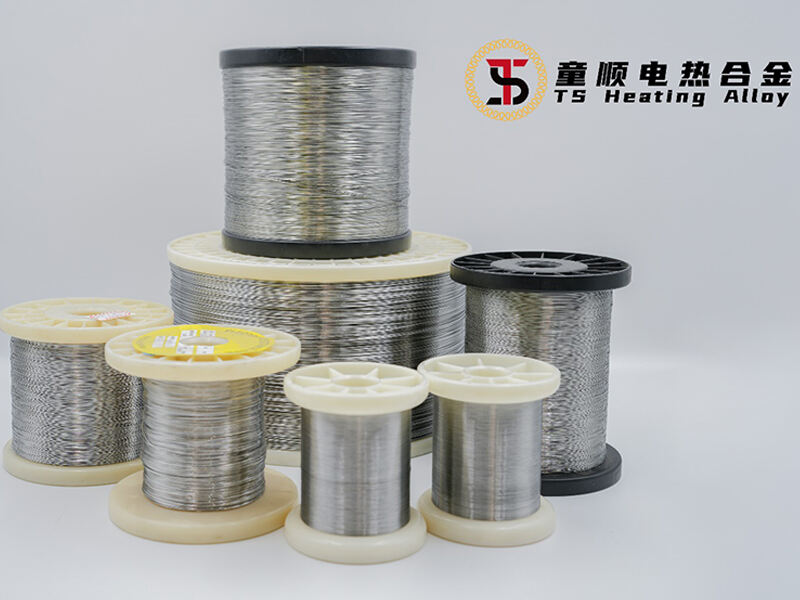

Iron-chromium-aluminum (Fe-Cr-Al) alloy wires are materials known for their excellent heat resistance, corrosion resistance, and oxidation resistance. They are widely used in both household and industrial sectors. These alloys are primarily composed of iron, chromium, and aluminum, offering high resistivity and good thermal stability, which makes them ideal for manufacturing resistance wires, heating elements, and more. Different types of Fe-Cr-Al alloys exhibit varying properties, especially in terms of temperature stability, corrosion resistance, and mechanical properties. Below is a detailed analysis of their industry applications and the differences among common alloy compositions.

(1) Household Sector

Iron-chromium-aluminum alloy wires are commonly used in household appliances for their excellent electrical heating properties. Typical applications include:

· Electric Heaters: The alloy wires are used as heating elements, providing rapid heating and maintaining a stable working temperature.

· Ovens and Microwave Ovens: Fe-Cr-Al alloy wires are used in these kitchen appliances for heating food, efficiently converting electrical energy into heat.

· Water Heaters: Due to their high-temperature resistance and oxidation resistance, these alloy wires are ideal for use as heating elements in water heaters.

In these applications, Fe-Cr-Al alloy wires provide stable performance and ensure long product lifespans.

(2) Industrial Sector

In the industrial sector, Fe-Cr-Al alloy wires are widely used as heating elements and electrical components in high-temperature environments:

· Industrial Heaters: In industries such as metallurgy, power generation, and chemical processing, Fe-Cr-Al alloy wires are used as resistance heating elements. Their stable resistivity at high temperatures makes them ideal for various high-temperature heating applications.

· Furnace Elements: The alloy wires are used in the heating elements of furnaces, especially in high-temperature furnaces, where they can withstand temperatures above 1500°C.

· Heat Treatment Equipment: Fe-Cr-Al alloy wires are also used in heat treatment processes, metal casting, and glass production, where precise and efficient heating is required.

Due to their high resistivity and excellent high-temperature performance, Fe-Cr-Al alloy wires are particularly suited for industrial equipment that operates under extreme heat conditions.

The specific composition and properties of Fe-Cr-Al alloy wires vary mainly based on the proportions of chromium, aluminum, and iron, as well as the inclusion of other elements like molybdenum, titanium, or niobium. Below are the characteristics of some common Fe-Cr-Al alloy wires:

(1) 0Cr25Al5

· Chemical Composition: Approximately 25% chromium (Cr) and 5% aluminum (Al).

· Properties: 0Cr25Al5 offers excellent oxidation resistance and high-temperature performance. It is widely used for heating elements in high-temperature environments. This alloy can maintain stable resistance and durability at temperatures up to around 1200°C.

· Applications: Suitable for heating elements, industrial heaters, and furnace components operating at high temperatures.

(2) 0Cr21Al4

· Chemical Composition: Approximately 21% chromium (Cr) and 4% aluminum (Al).

· Properties: Compared to 0Cr25Al5, 0Cr21Al4 has slightly lower aluminum content, which means its oxidation resistance is somewhat lower, though it still performs well at high temperatures. This alloy is typically used in applications where the temperature does not exceed 1000°C.

· Applications: Suitable for heating elements in household appliances, electrical heaters, and industrial heating elements in medium-temperature environments.

(3) 0Cr21Al6Nb

· Chemical Composition: Approximately 21% chromium (Cr), 6% aluminum (Al), and a small amount of niobium (Nb).

· Properties: This alloy offers superior oxidation resistance and corrosion resistance at high temperatures due to the presence of niobium. It is ideal for environments where temperatures exceed 1200°C.

· Applications: Used in high-temperature heating elements, gas heating devices, metallurgy, and power generation industries, particularly in heating elements inside high-temperature furnaces.

(4) 0Cr19Al3

· Chemical Composition: Approximately 19% chromium (Cr) and 3% aluminum (Al).

· Properties: This alloy offers good oxidation and thermal stability at high temperatures, but due to its lower aluminum content, its oxidation resistance is slightly weaker compared to other alloys. It is best suited for lower to medium temperature environments.

· Applications: Used in household appliances like electric water heaters and ovens, as well as in heating elements for low to medium-temperature industrial applications.

Iron-chromium-aluminum alloy wires are widely used in both household and industrial heating applications due to their excellent heat resistance, oxidation resistance, and electrical heating properties. The specific composition of the alloys, such as 0Cr25Al5, 0Cr21Al4, 0Cr21Al6Nb, and 0Cr19Al3, impacts their high-temperature stability, oxidation resistance, and resistivity. Choosing the right alloy depends on the specific working environment, temperature requirements, and durability needs of the equipment in which the alloy is used.