Make wires connecting the world.

These are the ones that offer various applications and is a device which generates heat. These heaters use a unique technology that allows them to heat up quickly and evenly. Wire wound heaters can be used for heating liquids and for keeping things warm in cold conditions. Here we will inspect what Resistance Wire wound heaters, how they function and what is the reason behind them being so valuable to us

Wire wound heater technology has a very simple construction behind it that works really great! The wire is made of a special alloy metal that does not melt or lose its shape at high temperatures. As the current runs through the wire coil, it produces heat in a process termed Joule heating. That is, as the electrical current moves through the Fe-Cr-Al Wire, it produces heat. The resultant heat dissipates into the surrounding environment, warming it up and making it more comfortable.

Wire wound heaters are versatile, and can be used in a number of applications. For illustration, they are being used to heat liquids, such as water or oil, in industrial processes. This is significant at many factories where manufacturing at a high temperature is required. Also, these heaters are perfect for warming items during the cold. You may feel them in heated blankets that help you stay warm at night or in heated car seats that help heat you up during a cold commute. Furthermore, cooking devices like ovens and stovetops use Ni-Chrome Wire wound heaters for efficient and even heating of food. It makes cooking simpler and more efficient.

The principle of wire wound heaters is to convert electrical energy into thermal energy. As the electrical current passes through the wire coil, its resistance heats the wire. This means the wire gets hot since it needs to labor to allow the electricity to pass through it. The heat produced is then dissipated and utilized in the coil's respective surroundings. The wire coil is specifically designed to heat evenly and quickly, which makes wire wound heaters a much more efficient and effective heating resource.

The wire wound heater has a lot of great benefits. First, they are efficient — they use less energy to produce heat. Secondly, they are dependable, which means you can always trust them to perform well when you need them. Third, they are straightforward, which matters when you are trying to heat something up quickly. These heaters warm up quickly and supply warm air evenly, serving the needs for various purposes. Wire wound heaters are also designed to last a long time so they can give effective heat for many years. In conclusion, wire wound heaters are the best thing for you if you want to have something that actually performs well and is long lasting.

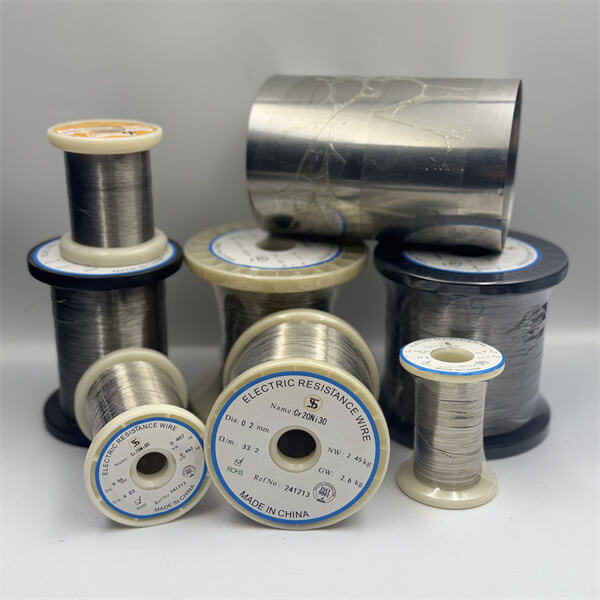

TS Heating Alloy Materials Co., Ltd is equipped with cutting-edge technology, including wire drawing machines, annealing furnaces, and packing machines. This ensures that every product, from raw materials to finished items, meets stringent quality standards. The company’s production processes are designed for precision and reliability, enabling the manufacturing of high-quality resistance wires and steel wire ropes. Whether it's Fe-Cr-Al or Ni-Cr wire, our products are crafted with care and expertise, ensuring optimal performance in various industrial applications.

Located in Taizhou, Jiangsu, China, TS Heating Alloy Materials Co., Ltd benefits from its proximity to Shanghai Port, one of the world's busiest shipping hubs. This strategic location facilitates efficient international shipping, allowing us to offer timely delivery to markets across Asia, Europe, North America, and Africa. Our logistics capabilities ensure that we can meet global demand quickly and reliably, making us an ideal partner for companies looking for high-quality alloy wire products with fast turnaround times.

With dozens of material types available, TS Heating Alloy Materials Co., Ltd offers a broad selection of resistance wire and steel wire rope products. This variety ensures that we meet the specific needs of diverse industries, from construction to specialized sectors requiring resistance wire ropes. Our ability to supply both standard and custom-made solutions makes us a one-stop shop for businesses worldwide, providing versatility and flexibility to cater to various market demands.

Since its establishment in 2023, TS Heating Alloy Materials Co., Ltd has expanded its international footprint through strong trading partnerships. Our products are now successfully exported to regions such as Japan, South Korea, Southeast Asia, Europe, and Africa, with an emphasis on fostering long-term relationships. By continuing to develop the TS Heating Alloy brand globally, we aim to increase recognition and expand our presence in international markets, offering high-performance alloy materials to customers worldwide.These four points highlight TS Heating Alloy Materials Co., Ltd's strengths, showing its commitment to quality, customer service, and global expansion.